Wow. It has been so very very long since an update!

TL;DR

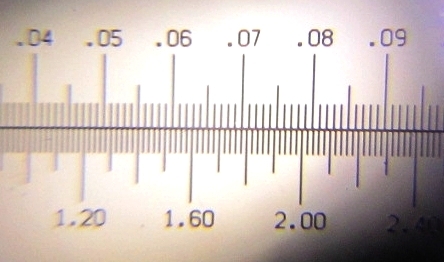

The local machinist is brilliant! We’ve managed a couple of good prototypes. Got a superb custom reticle (HUGELY expensive, but necessary!) from an American company. This past couple months struggled with and found a solution for what I describe as ‘barrel distortion’ in the view. Got (several different) new lens kits and have re-machined the ‘bottom optic shell’ a couple times. We’ve about got it right! Picking up what we think is the final machined version this afternoon or tomorrow morning!

The longer version

So, the new machinist with the fancy machines: Constant, a brilliant guy from South Africa, with not just one but FOUR of the fancy precision lathes and decades of experience! Designer Jon and I met with him (last year!) and went over the drawings. A few tweaks and adjustments, and Constant produced the first prototype body: (it has, like, 14 pieces!). He has since helped (tremendously!) with redesigning suggestions and remaking parts as needed. (We’ve run through 3-4 barrel prototypes, a few other bits and pieces.)

The new reticles (also hugely expensive) came and checked out really well! The eyepiece lens kit came and works beautifully in the new eyepiece shell. The … sticking point … has been the bottom optic. When the whole prototype was put together, there was … distortion on the outer edges. (What I describe as ‘barrel distortion’; there’s a name for it, but I can’t remember it.) The scope focused okay, but the scale (the reticle) sort-of … expaaaaanded to read too long (on both the NIST block and the standard slide). Could get it focused, but then … oops.

Jon the designer came and our one-hour meeting ran five hours – BUT we worked out how to fix it! First, dumped the objective lens kits ($$ ow.) and ordered samples of two new lenses (different size from the first set to provide/allow for an aperture). New bottom optic “shell” from Constant, expanding the ‘space’ for the new top lens in the objective lens shell. New spacer and retaining ring (which I’m calling a “retaining star,” cause it looks kinda like that). Got all the parts in this past week-or-so, and I put the first (bottom) lens (very tiny, barely convex, so make sure it’s right-side-up!) And it fit great. Next, the lens spacer… Oh hell. Won’t go in at all. Juuuuast barely too wide. (It’s OTS, and it’s SUPPOSED to fit.)

Discussion with Jon and Constant. Ah, if we expand the ‘bottom well’ in the bottom optic shell, just enough to let the spacer in, NOT enough to let the lenses slide around, it SHOULD work! SO, Constant is redoing the bottom optic shell — probably as I write this! – and I hope to pick three prototypes up tonight. (It is SO wonderful to have both the designer AND the machinist within easy driving distance!! CONVENIENT!)

So, fingers crossed this is the final tweak needed. Plan is: if this IS it; I’ll be ordering ten of everything, assemble ten scopes and ten trial gauges. I have several customers who’ve been helpful (for YEARS!) testing the prototypes in their actual work, and so they and my major distributors will get a chance to whack ‘em around and see how they do. In the meantime, I’ll be trying to find a way to mass produce them that will NOT cost an arm-and-a-leg so I can put them into actual production.

I know, over the past … since April 2012 (so, five years and four months!) I’ve been saying; I’m hopeful, I think maybe THIS time I’ve got it… and then it wasn’t. But — I REALLY think that this time I may have it!!

Wish me luck!!