TL;DR: In several months, the new Dual-Measure scopes will be in production and available.

I have the (final: YIPPEE) prototypes of the new enhanced (“Dual-Measure”-reticle scope) gauges out for review by distributors, some NACE instructors, and the couple of customers who’ve been testing my prototypes for, lo these many years. (I started working on the new scopes in April 2012.) So far, the reviews are stellar! (And I am just deliriously happy with the scopes.)

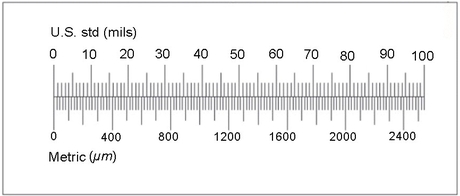

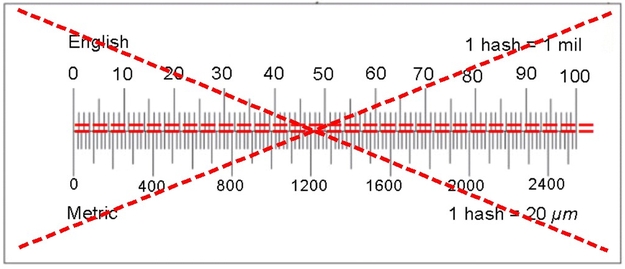

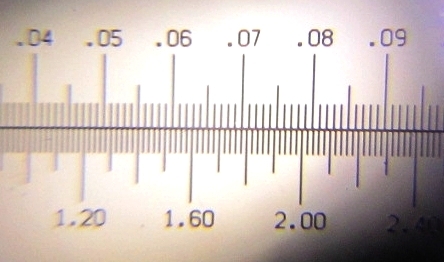

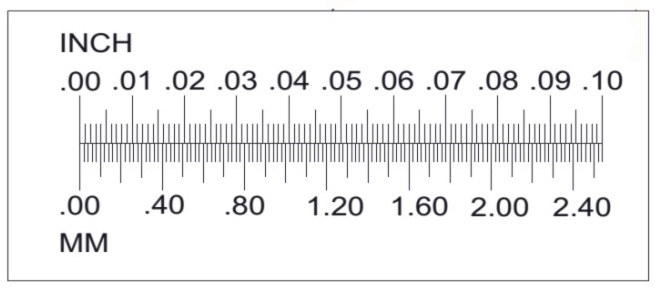

I’ve already “re-designed” the reticle twice – in the first week – here’s the current/latest, probably final, drawing. I’m getting some brilliant suggestions, and a number of version of: “Very happy to see your progress! Excited!!!” and “It looks awesome. Love the new optics and the really easy-to-read scales.” and “3 thumbs up.”

Approximate timeline

I’m still working up a more-formal schedule, but my approximate timeline looks like this:

- Review period ends around the end of April.

- A week for me to collate, synthesize, and send back out the comments, suggestions, objections, and requests for final review.

- A week or so for final comments.

- Set the reticle designer to redoing the final design (this is my third reticle design – but I don’t regret the $$$$ {wince} AT ALL!) and a couple weeks for them to send me a final prototype.

- Then set the reticle maker to making several hundred new D-M reticles. So, a month-plus for delivery?

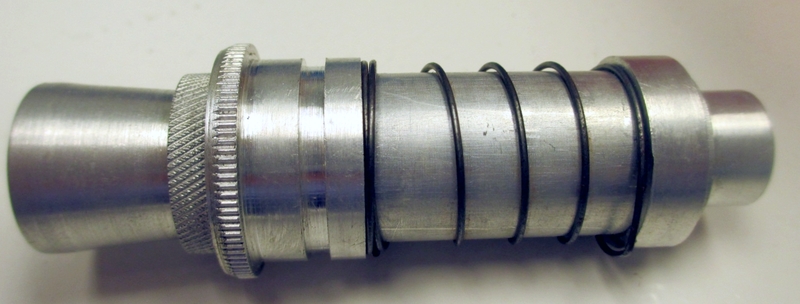

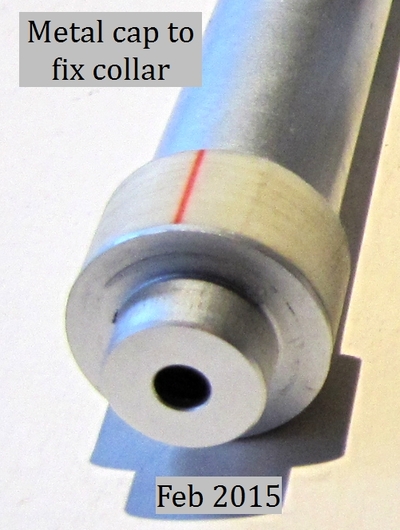

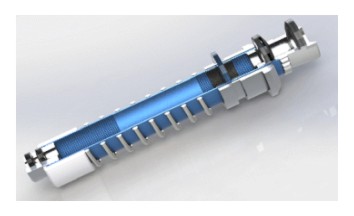

- At the same time, my new (subcontractor) machinist sets to work making several hundred of the whole-lotta-parts that make the new scopes. (Don’t want to pull the trigger till I’m SURE I’ve got it right!)

- And I order several hundred of the other lens kits (two kits of two lenses).

- When everything arrives, I sit down and assemble (well, get a start on assembling) several hundred scopes; and a whole bunch of new gauges.

All along, my first (subcontractor) machinist (whom I call “The Blessed Harry” – because he has “saved” me multiple times) is making me boatloads of metal bodies (OG202; soon-to-be the OG212!); and I’m doing all the prep work and fitting out on a boatload of plastic body-shells (OG204; soon-to-be the OG214!); so they’re ready for immediate assembly when I get the scopes in-hand.

So, I’m figuring … several months till the new Tooke Gages with the new enhanced “Dual-Measure” scopes are into full production. (It is my oft-stated goal to get the universal scopes out of the coating field entirely!)

New programs and more changes

And, oh yeah, I’m designing and preparing to implement several new programs:

- the (already in operation) Body Transplant program. Info on my site: and a customer ‘testimonial’ on the blog: (upgrade your old body using your old-style scope).

- the (waiting on the D-M scopes) Scope Swap program (get rid of your universal scope for a brand-new D-M scope)

- the (waiting on the D-M reticles) Upgrade your Old-style Scope program (yes, of course I made sure the new reticles would work in the old gauges!)

And, the biggie: I will FINALLY be able to make some noise and let the coatings world know that Micro-Metrics is still here and still great! I have not advertised since Michael died (and he never did any advertising)… but with the new scopes, I finally have a product *I* am totally happy with! Hoping this results in me and my distributors being “burdened” with lots and lots of sales!

And, in and around all that I’m re-doing the website and the Technical Data Sheets entirely: both of which, I realized, have way Way WAY too much text. (I’m a technical editor by profession: it’s an addiction). I’m creating a new “Quick Start” card (cause there needs to be one)! Further down the pipeline is a set of short videos on use and calculating and other info.

The next big project

Once I have the new scopes and gauges into full production, my amazing new industrial designer and I are going to start on the next big project: a Tooke Gage camera adapter! I welcome any suggestions, desires, and ideas for the camera adapter. I already have a long list of folks who want one, so give me ideas and/or get on the list to be notified when the project succeeds! The designer says it won’t be a huge problem — and HE is the one who was finally able to get the new D-M scopes correctly designed!

Major major thanks to:

- Harry Robinson (“The Blessed Harry”) of Robinson Racing Enterprises (just 9 miles away, here in Cumming GA) who does my designs (starting the month after Michael died) and the necessary CAD programming — and the even more necessary hand-holding when I needed it. And Sandra who runs Harry’s CAM (and does some of the CAD programming) and makes my parts!

- Jon Butler of Apex Designs over in Gainesville GA (just ~30 miles)

- Constant Laubscher of Lazerlinez (just 13 miles) — the machinist who had the necessary “5-axis precision lathe with precision milling capabilities and a push bar” — which was the beastie necessary to MAKE all the scope parts (and he has FOUR of these machines)! (And he has been exceedingly patient as we tweaked and asked for yet-another prototype scope part.)

- Tim Loden, my SCORE adviser, who has been beyond-helpful as I work out all the changes that are coming. When I made my first appt, he emailed me on Friday before the first (Monday) appt and asked if I had read his resume before making the appt, “or was it just dumb luck?” Huh? Nope, hadn’t read it. HE turns out to have worked for 25 years for one of my major corporate customers! He has been IN this field for most of his career! (He’s a consultant now.)

OH NO!

OH NO!