Pictures updated Oct2014: Visit the CTH02 website page here:

http://www.micro-metrics.com/CTH02.htm

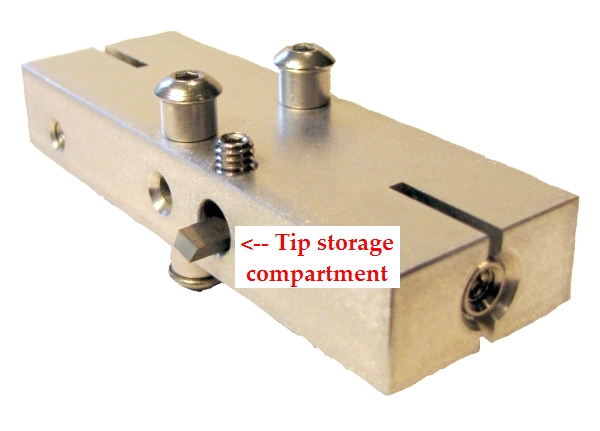

Our new machinist has a purchase order in hand to machine 20 new longer (double-sided) cutting tip holders. I used an old example that we measured to create the new drawing from, but the new ones is much prettier!

This holder allows two tips to be mounted on opposite sides and, like the shorter, single cutting tip holder (CTH01), allows easy use of the cutting tips without having to manipulate the Tooke Gauge to make the incision and then manipulate the gauge again to view the incision through the microscope.

With this tip holder, you can:

- make multiple incisions with your most-used tip(s) without having to keep switching the gauge to viewing position

- mount two of the same tip to allow for checking two incisions against each other

- “bracket” your incisions by mounting two different tips to create different incising geometries

Some of our customers have said they prefer the larger tip holder because it’s easier to handle than the smaller one. Others prefer the smaller one because it fits easily in a pocket.

(Obviously, I’m holding this one upside down so the tip shows.)