I spend part of my time reading business sites around the web (always more to learn) and I came across a website holding a contest called “Five Tips for $5,000.” The direction suggested:

share your advice for business start ups or small businesses along with your name, email, website, business name, short bio and a head shot to accompany your five small business start up tips, and you will be entered for a chance to win $5,000.

I felt I had some lessons to share from nearly 3 years of running Micro-Metrics, so I whipped up my five tips and submitted them, and then continued reading my way around the web. Several months later I got a phone call saying that my entry had been chosen the winner!! AMAZING!

Here’s what I wrote:

Elenor Snow – President, Micro-Metrics Company

www.micro-metrics.com

I “became” a start-up (I was a ‘kept wife’) when my husband died suddenly and left me a manufacturing company. I had helped out in his company and heard him on the phone with customers for 16 years, but never even thought of owning or running the company! Here are my painfully gained lessons.

- Prioritize! Handle everything you can, and no more than that. If some part or process is a money-costing problem, work on it till it’s fixed; leave the other stuff till later. And don’t stress about it — you can only do what you can do: everything else has to wait.

- Triage! If you’re stuck with multiple or awkward steps to get something done, but it DOES get it done, and there is something else that is not getting done? Streamline or replace the awkward-but-working processes after you have everything actually working!

- Learn! In two years, I’ve read seven accounting books. (I do my company accounting; my accountant does my taxes.) I hired (by the hour) a math-and-engineering professor to teach me the arcane math I may have to explain to customers. I read business books at night.

- Create a verbal self-image (a personal ‘elevator-speech’)! I use this one: “I’m the youngish widow who doesn’t resist asking for help and advice.” By defining myself a certain way, I am able to overcome any internal resistance to asking someone for help (even though I’m a bit shy).

- Ask for help! Despite being a ‘do-it-myself’ kinda gal, I seek info, advice, help. I sit with my (two) excellent machinists and describe a problem I’m having — and wisdom just falls out of their brains! My distributors taught me a lot about advertising. People love to help!

Incorporate.com, the company that ran the contest, also took my ‘brief bio and a few of my business goals” and wrote an excellent little introduction to me:

Forever Learning: The Elenor Snow Story

Little in Elenor Snow’s background prepared her for the discovery, in 2011, that she would be running her own manufacturing company.

That’s when her husband, Michael Ray Laurence, longtime owner of the Georgia-based company Micro-Metrics, passed away. Snow, an editor by profession, was suddenly in charge.

“I’d helped out a little but hadn’t paid much attention to how he ran the company,” Snow says. “Perhaps I should have!”

Despite the enormity of the challenge, the 58-year-old Snow stepped up and has adapted to her new leadership role with characteristic spirit and resilience. In fact, her wise, good-humored advice is exactly what led The Company Corporation’s judges to name her winner of its recent “5 Tips for $5,000” contest.

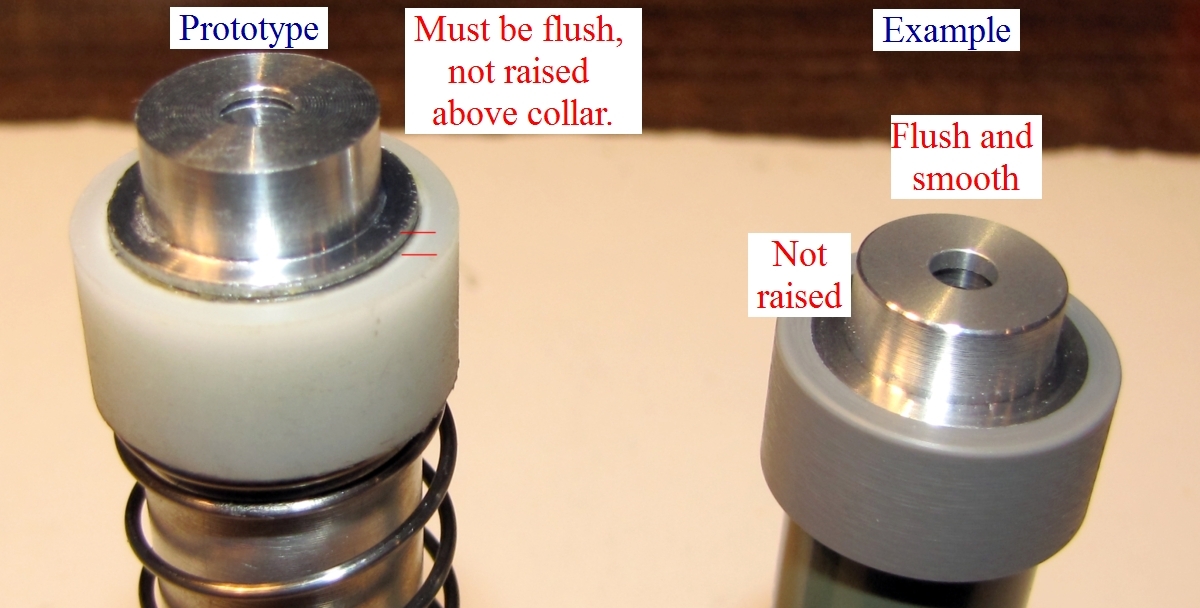

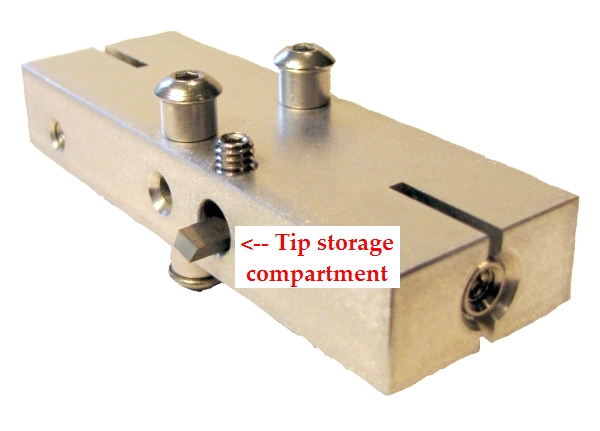

Founded in 1961 and located in a suburb of Atlanta, Micro-Metrics manufactures precision devices used to inspect a variety of coatings and films. After taking the company’s helm, Snow’s first business goal was to update its processes and components. “For me, the cue for what to replace next is: what is frustrating me the most at the moment?” she says. “If a 30-year-old process takes days to get through, then it has to be replaced with one that takes much less time and frustration.”

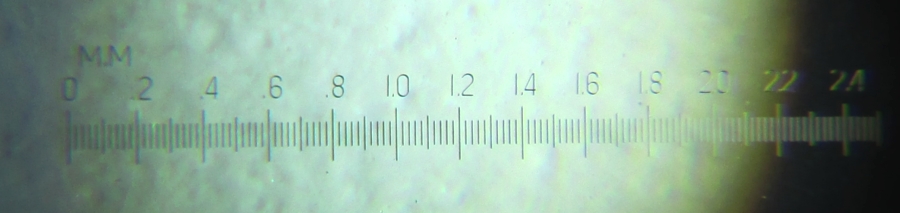

Snow’s second goal was to keep Micro-Metrics’ products “relevant.” Currently she’s arranging for custom-made microscopes that are more precise than the current tools on offer. The project has been two years and many thousand dollars in the making, but a production-ready model is just around the corner. And while Snow admits that the project is “frighteningly expensive” (paying for the new scopes will cost nearly one-third of the entire cash resources of the company), she’s convinced it will be a long-term win for Micro-Metrics.

Snow’s third business goal is to increase sales. She has spent very little on advertising since taking over the company, but with those new scopes in the pipeline, she plans to get the word out to the trade in a big way. “I’ve been gathering resources, studying what ads and articles are out there, and consulting with my local SCORE advisor – preparing for an ‘ad blitz’ once I have the better scopes in hand.”

Her secret weapon? Curiosity.

“In two years, I’ve read seven accounting books. I hired a math-and-engineering professor to teach me the arcane math I may have to explain to customers. I read business books at night,” she says. In fact, self-improvement is Snow’s number-one priority as she moves Micro-Metrics forward. “My goal is to get smarter both about business and about the niche in which I find myself!” she says.